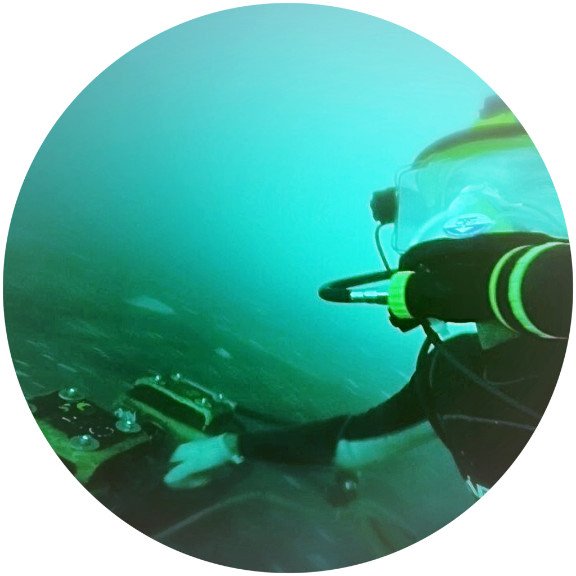

Inspeção com fotos e vídeos digitais de estruturas submersas e embarcações para verificação de existência de incrustações, condições de proteção catódica e danos como trincas, amassados, vazamentos, arranhões, empenos, enroscos que podem ser causados por toques de fundo, acidentes, desgaste natural ou fadiga de material. Todas as inspeções são acompanhadas de um relatório técnico descrevendo os itens verificados e suas características.

Vistorias com Classe junto aos vistoriadores de diferentes entidades pertencentes a IACS pelas quais somos certificados incluindo, DNVGL, ABS, Bureau Veritas, NKK, Lloyd´s Register, Korean Register e RINA, sempre com o uso de sistema CCTV de monitoramento em tempo real e incluindo medições de folga de eixo de leme e desgaste do eixo de hélice, são acompanhadas também de relatório técnico incluindo os resultados verificados e suas descrições detalhadas assim como DVD com a gravação do vídeo da vistoria.

A limpeza de casco e acessórios de embarcações elimina a incrustação que cresce durante o período de estadia nos portos. Incrustações aumentam a resistência durante a navegação, fato que consequentemente aumenta o consumo de combustível. Os benefícios da limpeza gera economia de combustível e aumenta a vida útil da tinta do navio e também o período entre docagens secas, melhora a visualização das condições gerais do casco e acessórios para requisitos de Sociedades Classificadoras. Nosso equipamento hidráulico de escovas rotativas de limpeza é de alta tecnologia e temos a disposição uma grande variedade de escovas que vão de suave, chamadas de “soft”, mais seguras para a tinta do navio até um pouco mais agressivas para situações críticas chamadas de escovas “hard”. Alguns modelos incluem até facas para auxiliar no corte de incrustações de grandes dimensões.

Super polimento de hélice reduz a aspereza da superfície das pás até o nível A/B dentro da escala comparadora Rubert, garante máxima propulsão, minimiza o arrasto e otimiza a hidro-eficiência do hélice e gera uma economia de combustível de até 3% em alguns casos, isso tudo sem contar os benefícios da redução do stress sob o qual o eixo do motor e o próprio motor é submetido. Esse é um meio altamente efetivo para manter a performance de um navio e também fácil de integrar em estadias portuárias pelo fato de poder ser executado com navios atracados garantindo que não há perda de tempo operacional ao operador do navio.

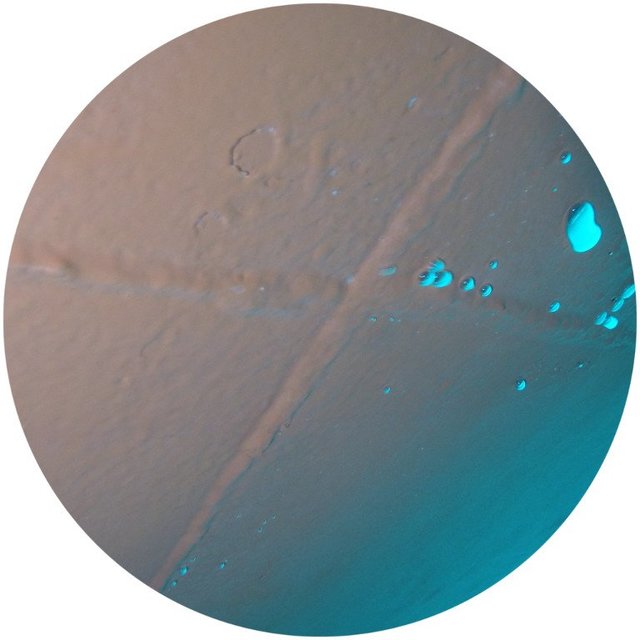

Remoção de enrosco no guarda-cabo permite um perfeito funcionamento do eixo propulsor e evita possíveis danos ao hélice e/ou motor principal. Redes e linhas de pesca, cordas, cabos de amarração são constantemente encontrados na parte do eixo que fica que no interior do guarda-cabo. Até mesmo quando facas são instaladas o enrosco acaba acontecendo.

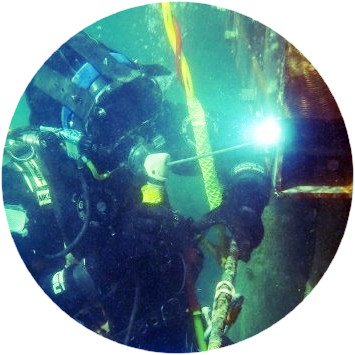

Soldadores certificados e prontos para executar serviços a seco e dentro d´água. Temos o know-how para trabalhos que exigem instalação de cofferdams (caixas secas) conseguindo executar serviços de solda internos com o navio dentro d´água gerando economia de tempo e dinheiro. Fornecemos chapas e metal certificado e estamos prontos pra elaborar procedimento de solda diversos, customizados para cada caso e cliente.

Stop-hole ou solda com ensaio não destrutivo e teste de ultrassom através de procedimentos que atendem todas as necessidades. Bujonameto e tamponamento de válvula dentro e fora de caixas de mar para reparo interno. Somos experientes no assunto e damos o suporte necessário durante o reparo com a urgência ne cessária para atender qualquer emergência.

Taxa de sucesso de 80%, nosso método de resgate de âncora e corrente gera economia para nossos clientes e sem interferir no tempo de operação e estadia.